- Home

- Success Stories

- TLV's BPSTM® program streamlines maintenance and reduces costs at MM21 DHC

TLV's BPSTM® program streamlines maintenance and reduces costs at MM21 DHC

This company has revolutionized their steam trap inspection and management by transitioning from TBM to CBM, reducing labor and improving efficiency.

Minato Mirai 21 District Heating and Cooling Co., Ltd. (MM21 DHC) has been focusing on improving the efficiency of their heat supply systems by focusing on steam trap management. However, with the large number and variety of steam traps installed over an extensive area, the conventional maintenance procedures were no match. Implementing TLV's steam trap management system enabled a shift from time-based maintenance (TBM) to condition-based maintenance (CBM). This delivered significant labor savings by reducing the workload required for maintaining the steam traps.

Minato Mirai 21 District Heating and Cooling Co., Ltd. (MM21 DHC)

| Location | Yokohama, Japan |

|---|---|

| Business Operations | Heating and cooling with the supply of steam, and hot/cold water, etc. |

| Application | District Heating and Cooling |

Services used:

- Steam trap survey

- Best Practice Steam Trap Management (BPSTM®) Program

Problem

The maintenance of steam traps has become increasingly difficult as the number and types of steam traps have increased over time.

In the 1990s, a combination of annual inspections and monthly patrols was enough to address any steam trap related issues. However, as the variety and number of steam traps increased over the years, maintenance also gradually became more complex. Around 2008, several major companies moved their headquarters to the area, which led to an extension of the steam piping in the Minato Mirai district and increased the total number of steam traps to over 300. Consequently, these inspections required two months of work by three to four people. Given that the steam had to be supplied as far as 2 km [1.24 mi] from the boiler, the conventional maintenance methods would no longer suffice.

Reason for contacting TLV

MM21 DHC had consulted TLV multiple times for solutions before

When operations began, steam traps from several different manufacturers were used. However, due to the superior quality and fewer malfunctions of TLV's steam traps, there was a gradual shift towards TLV products. The turning point came when the frequent visits from a TLV's sales representative provided an opportunity to discuss the challenges associated with maintenance.

Solution

Outsourcing steam trap inspections and visualising the steam system

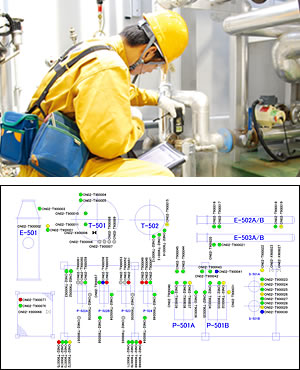

The "TrapMan Survey" service was adopted in order to conduct condition-based maintenance, which involves accurately diagnosing the condition of steam traps and implementing planned actions when abnormalities are detected. The TrapMan Survey is a steam trap survey capable of assessing operational conditions and quantifying steam leakage of any steam trap, regardless of their manufacturer or model. The survey is conducted by certified TLV professionals using specialized diagnostic tools and is able to be conducted faster and more accurately than self-inspections. In addition, TLV swiftly provides comprehensive reports, ledger books, and plant maps (diagrams displaying the steam trap diagnostics), enabling immediate actions for replacements and clear insights into potential annual losses.

Results

Inspection and repair costs reduced by 10% and shortened the time required for inspections from 2 months to 1 week

Establishing a system to maintain steam system integrity and resolve labor shortages

Compared to the previous system of conducting inspections on all units, adopting this service led to repairs only on defective units. This change resulted in a significant reduction in man-hours required for maintenance. The total cost was reduced by approximately 10%, including inspection and repair expenses. Most notably, the inspections now only require one company representative to accompany a TLV member for a week, rather than 3-4 people taking up to 2 months to inspect the traps.

Addressing new challenges revealed through visualizing the steam system

Addressing Issues of Poor Maintenance and Further Reduction of Unaccounted Steam (Steam losses with no known cause)

Despite implementing the TrapMan Survey, the client conducted imperfect maintenance of faulty steam traps themselves, which sometimes led to recurring problems such as steam leaks and malfunctions. Moreover, even after replacing the steam traps, some steam was still unaccounted for. When TLV conducted an investigation, they found a small amount of steam leakage from newly replaced Free Float® steam traps. It was concluded that the steam loss from each steam trap was accumulating on a grand scale, leading to the problem of this unaccounted steam. With the visualization of the steam system, a new challenge arose: to identify and reduce this unaccounted steam.

Optimizing Condensate Discharge Locations through Steam Trap Management

To address the issues with steam trap leaks and recurrent failures, TLV introduced a new approach of optimizing condensate discharge locations (CDLs). The new steam traps were energy-saving Free Float® types that could be used in heat exchangers. However, in steam transport pipes where the condensate produced is minimal, these traps were generating a small amount of steam loss. In order to further reduce steam loss, these steam traps were changed to Free Float® traps for main lines with three-point seating. Further, the BPSTM® (Best Practices of Steam Trap Management) program was adopted, which includes CDL optimization by selecting the appropriate model based on the conditions.

Reducing Steam Leakage from Steam Traps and Reducing Recurrent Defects to Zero

As a result of implementing this program, MM21 DHC were able to successfully reduce the average steam loss per CDL from 1.5 kg/h [3.3 lb/h] to 0.1 kg/h [0.2 lb/h] or less and recurrent failures in the steam trap system were eliminated. The program also led to improved efficiency in terms of internal labor, as it clarified the selection process for the optimal steam trap and replacement procedures and reduced tasks related to internal coordination and verification.

Customer's voice

Plant management

Assistant Director, Mr. Horiuchi (pictured left)

Associate Officer, Mr. Onobuchi (pictured right)

* Accurate as of 2019

We were considering outsourcing our maintenance work due to increasing workload in the future, but TLV proposed the TrapMan survey and it proved to be a success in streamlining our processes. With TrapMan, we were able to allocate our internal resources to manage other equipment, ensuring stable heat supply in the Minato Mirai area. After implementing TrapMan, we still faced issues with trap repair and steam loss from normal traps, so we decided to adopt the BPSTM program for further improvement. With the continuous use of both TrapMan and BPSTM programs, we are now able to keep our failure rate below 5% annually and almost no steam loss, allowing for peace of mind when managing the plant.